I am one of the few, if not the only person alive who has commanded both 105 and 155 smooth bore mortar units in combat. My experience is in both hill fighting and in rapid advances in flat country. My experience was in the Philippine campaign during World War Two. I have in my log book 155 smooth bore rounds fired at 86 degrees elevation at 300 yards range. During the preparation for an infantry advance, we took out a Japanese tank, an anti-tank gun and three buildings used by the enemy for firing points. During hill fighting at the Villa Verte trail, after an array of artillery ranging from 105's to 8-inch howitzers had failed to take out a machine gun emplacement on the back side of a hill after two days of bombardment, our 155 smoothbore shells (with spotting help by a Piper cub pilot) took three rounds to adjust and ten rounds for effect. To my knowledge, no other large smooth bore mortar work aside from ours was done during World War II.

The 105's were conventional inertia operated muzzle loaded barrels, the 155's were also muzzle loaded but they had firing mechanisms in the bases of the barrels. The 105 shells weighed about 22 pounds and the 155 shells weighed 65 pounds with a 19 pound charge of TNT. These were awesome weapons. I took the mortars over for testing during the Philippine campaign as a secret project to introduce and evaluate them. Neither weapon was well developed nor did they have adequate range as shipped; the 155 had only 2500 yards range while the 105 had a pathetic 2000 yards max range. In the case of the 105's, I knew the barrels were good for 5000 yards range, but the base plates would fail at more than 2000 yards range.

I designed new base plates, 6th Army shops built them, we proof fired the weapons and put the 105's in service at 4800 yards range and they performed beautifully. I was an ordnance officer, but 6th Army headquarters gave me a section of marvelous infantry mortar men and so I found myself as an amateur commanding a group of professionals. It worked out quite well, as a matter of fact, General Kruger, commandant of 6th Army wrote us a commendation enumerating part of our score. After spending several weeks on and near the infantry line, I concluded and reported that rifled bore mortars are ineffective because the rounds have to be fired at about 60 degrees max so the rounds won't "boat tail" in as duds. In addition, the smooth bore mortars appeared to be more accurate to me, even though the 4.2 inch chemical mortar did some good work, but the lack of drift from spinning in the smooth bore mortars and the inability of rifled mortars to drop shells in almost vertically left me totally convinced that smooth bore is the only way to fly.

My experience in R&D at Aberdeen

included test firing nearly everything from the 60mm mortar to the 8-inch howitzer,

and even the German 88 and some Russian weapons. Many people

lose sight of the fact that a rifled bore projectile will not turn over if fired

much beyond 60 degrees elevation, which is why all the artillery firing hundreds

of rounds were futile in taking out the machine gun emplacement mentioned

above. On the other hand, perhaps it is worth thinking about a 155

rifled bore mortar similar in concept to the 4.2 inch Chemical Mortar so the

current variety

of 155mm howitzer rounds can be used. When you fire a mortar, you employ

the cheapest and lightest recoil mechanism ever invented, the earth. The earth

both restricts the recoil distance so that less energy is transmitted and you

very economically turn the recoil energy into heat within the earth.

My experience in R&D at Aberdeen

included test firing nearly everything from the 60mm mortar to the 8-inch howitzer,

and even the German 88 and some Russian weapons. Many people

lose sight of the fact that a rifled bore projectile will not turn over if fired

much beyond 60 degrees elevation, which is why all the artillery firing hundreds

of rounds were futile in taking out the machine gun emplacement mentioned

above. On the other hand, perhaps it is worth thinking about a 155

rifled bore mortar similar in concept to the 4.2 inch Chemical Mortar so the

current variety

of 155mm howitzer rounds can be used. When you fire a mortar, you employ

the cheapest and lightest recoil mechanism ever invented, the earth. The earth

both restricts the recoil distance so that less energy is transmitted and you

very economically turn the recoil energy into heat within the earth.

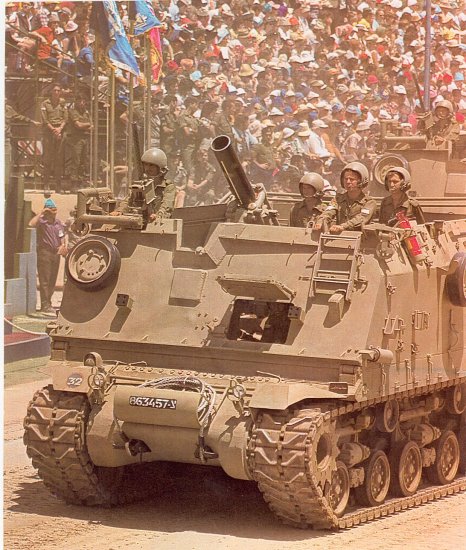

I think there might be a possibility of developing a 155 rifled bore mortar for 20 kilometers or so range, like the Israeli 160mm Soltam mortar (left). If so, it would offer the possibility of both light weight and economy. I picture the 155 smooth bore mortar as offering the possibility of a valuable close support weapon for up to 5 or 6 kilometers with no precession problems, it would also have the 360 degree "daisy cutter" fragmentation pattern of smooth bore mortars and beautiful digging ability. I pass all of this along because, I think having a weapon that can dig the enemy out of the far side of a hill with shells that can come in almost vertically could solve many problems for the line infantrymen. This is especially true since since both the the 105 and the 155 smooth bore mortars were serviced by sections of 8 to 10 men, and they could be quickly and easily hand loaded onto light vehicles.

Lloyd B. Smith Lbatre@aol.com

Ed. Despite the direct vertical plunging advantage of smooth bore fin-stabilized rounds, and the portability of lighter rounds, the key advantage of the proposed 155mm mortar, is ammunition commonality with 155mm howitzer systems (so they can fire the current variety of 155mm munitions). I consulted one expert who stated that modern 90lbs 155mm shells will turn over up to 85 degrees. Perhaps a longer, heavier fuze can be developed for even closer engagements to guarantee the round will turn downward.

On the other hand, the current 120mm smooth bore mortars are more mobile with rounds that are easier to manhandle, so perhaps they are better for infantrymen. I'd also like to know if 120mm mortar rounds can be fired from a modified 120mm tank gun fire so that "low blast" rounds can be fired directly over the heads of infantrymen. If the M1A1 tank guns could be altered for super elevation, they could double as mobile 120mm mortars carriers whose long, thick, smooth-bore barrels could provide tremendous range.

"The U.S. Army doesn't design guns to fight wars, it designs guns to make money"

Dr. Gerald Bull, the Canadian gun genius

©2001 www.G2mil.com